Widespread fires would soon be a thing of the past as a Department of Science and Technology - Philippine Council for Industry, Energy and Emerging Technology Research and Development (DOST-PCIEERD)-funded technology maps out fire hazards and where it may spread, helping authorities to outsmart the disaster.

Firecheck, a fire hazard mapping and fire spread modeling project implemented by the University of the Philippines - Cebu, seeks to provide emergency fire responders and officials, strategic planners, and policy-makers a wealth of information for fire disaster assessment and risk evaluation to be able to combat, if not mitigate, the negative consequence of fire.

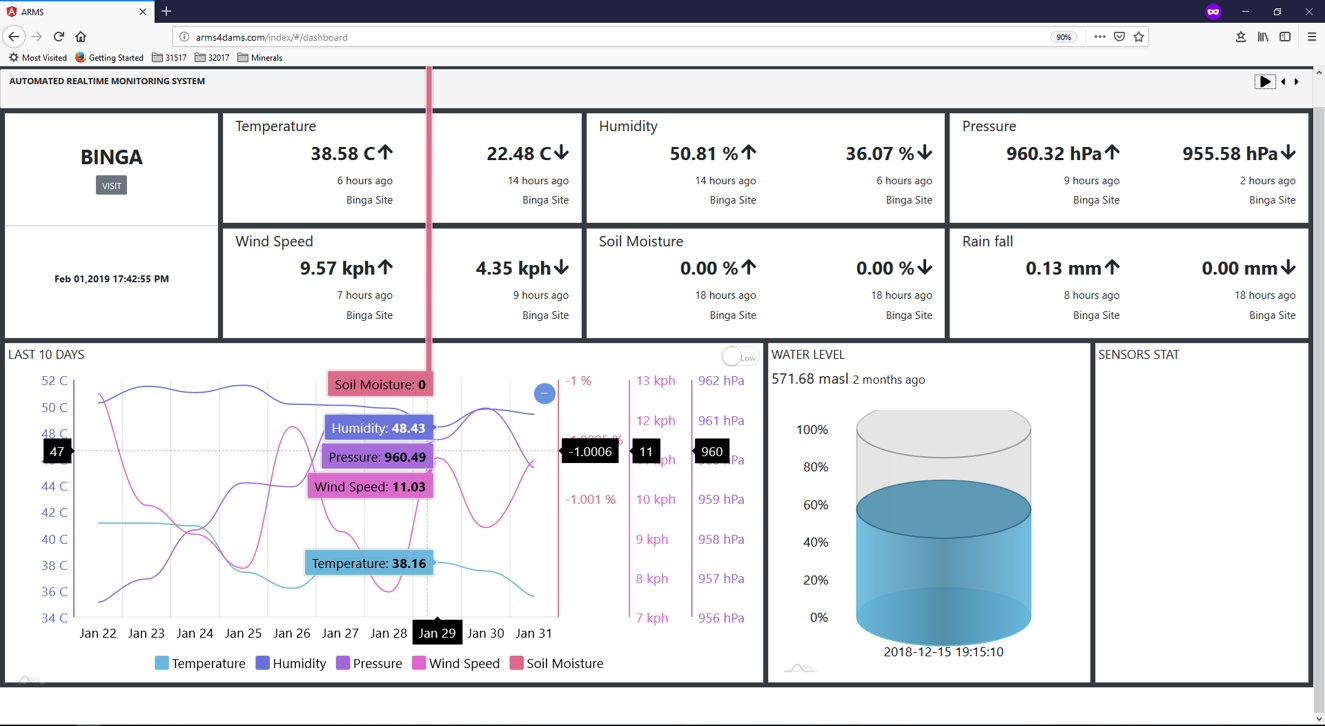

UP Cebu Professor and Firecheck Project Leader Aileen Joan Vicente said Firecheck’s hazard maps identify highly-dense residential areas in the cities that are prone to fire incidents considering the construction materials used in the area, building density, and urban heat island.

“Fire hazard mapping is a vital step in acknowledging fire as an inevitable disaster that must be accommodated similarly to how we prepare for disasters,” she said.

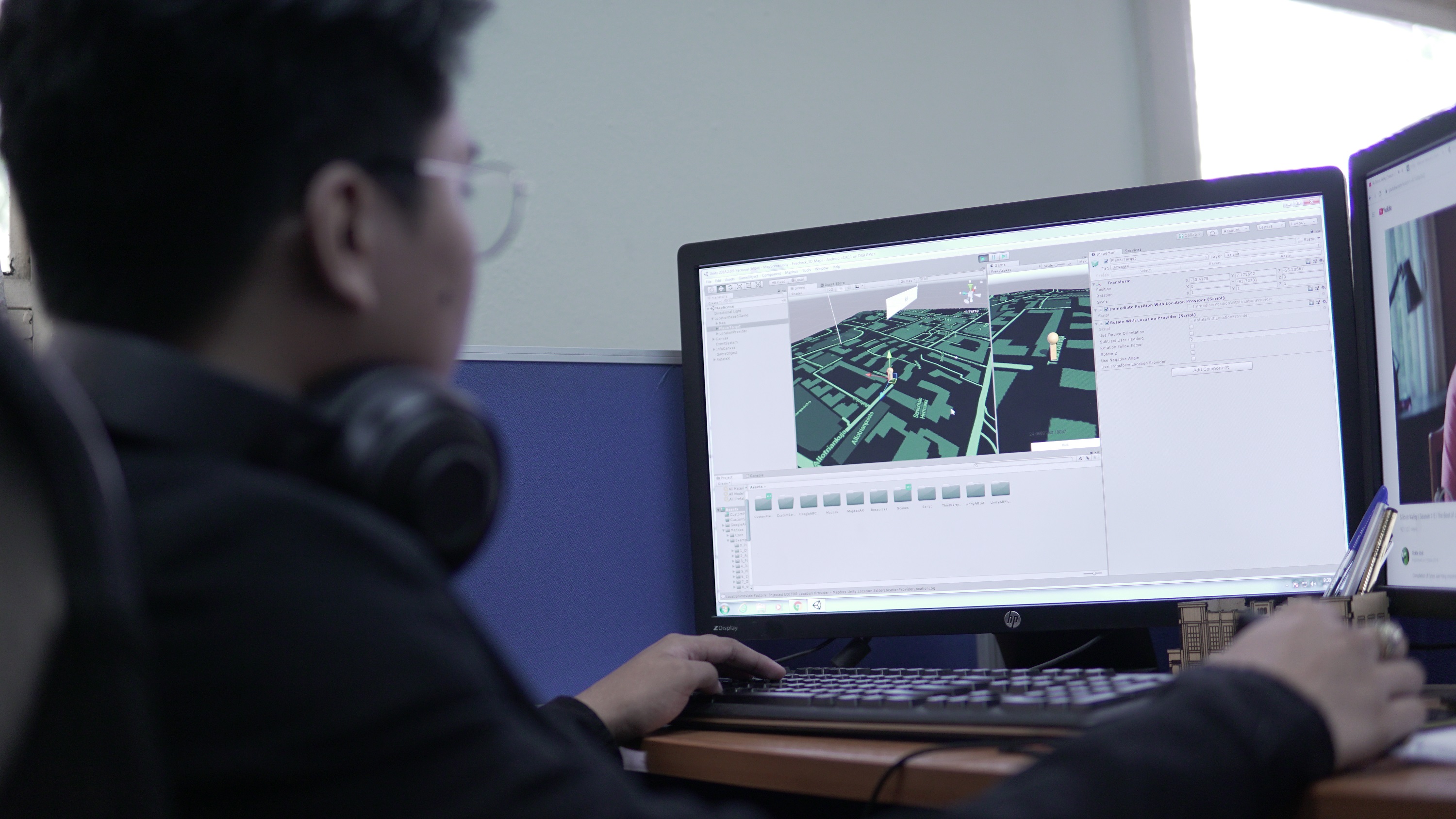

Vicente said that besides the hazard maps, her team also created 3D maps of high-risk communities and fire spread models and simulation that can provide predictive information on the possible extent of the fire and its potential damage.

She said that information from these maps, models, and simulations can be used to improve pre-fire plans, evacuation plans, and investment plans for fire fighting facilities and mitigation plans.

At present, Vicenete’s team is working with the Disaster Risk Reduction and Management Office, City Planning and Development Office, and Bureau of Fire Protection (BFP) Regional Office 7 to cover the cities of Cebu, Mandaue, and Lapu-Lapu in verifying the fire hazard maps that they have created.

She noted that they are also testing the FireCheck Attribution App, a mobile application that can display the community’s 3D maps tagged with information necessary for pre-fire response planning such as building properties and road attributes.

Vicente said that they have tested this app during their pilot field survey in Barangay Basak, Lapu-Lapu City and is now undergoing modifications to improve its features.

She added that her team will train more users on the mobile app, develop evacuation plans, and validate the generated maps.

“It is now high-time that not only Metro Cebu, but also the whole country, take a scientific and proactive approach to fire disasters based on adequate preparedness, prevention, and mitigation, ensuring that the fire will be put out even before it begins,” she said.

DOST-PCIEERD Executive Director Dr. Enrico C. Paringit expressed confidence that the project will greatly benefit fire authorities in mitigating and controlling damage with the use of modern technology.

“With Firecheck, we can provide a smart solution in increasing the community’s resiliency against fire disasters. We look forward to the day that Firecheck spreads across the nation and ignites the consciousness of our Filipino people in using technology to outsmart natural and man-made disasters,” he said.