The Department of Science and Technology on Wednesday (June 28) hailed four (4) outstanding research institutions for their exemplary implementation of research projects in 2022.

In line with the 13th Founding Anniversary of the DOST – Philippine Council for Industry, Energy and Emerging Technology Research and Development (DOST-PCIEERD), the research institutions received the Excellence in Project Implementation and Completion (EPIC) Awards for successfully finishing their projects with 100-percent budget utilization, on-time with no extensions, and meeting its targets, completely.

DOST Secretary Dr. Renato U. Solidum, Jr. congratulated the awardees and expressed hope that others will follow suit in ensuring that government funds are fully utilized.

“As we accord accolades to our project implementers for doing the job well, we now face the challenge of translating these research outputs to technologies that will help the country in wealth creation. We hope our researchers will take on an entrepreneurial mindset and bring these research outputs from their academic drawers to supermarket shelves,” he said.

DOST Undersecretary for R&D Dr. Leah J. Buendia also thanked DOST-PCIEERD for recognizing the efforts of project leaders in ensuring that researches are done efficiently and effectively.

“We look forward to more EPIC awardees in the future as we work hand-in-hand with our project leaders in ensuring an efficient and effective implementation,” she said. “DOST’s support to industry-academe partnerships in the country through the CRADLE program and PCIEERD-funded projects has been very evident in the EPIC awards. There was a clear need for innovation and DOST programs answered the needs of Filipino companies.”

DOST PCIEERD Executive Director Dr. Enrico C. Paringit regard the 2022 EPIC awardees to be exemplars to other project implementers in the country.

“May the EPIC awardees inspire other researchers and research projects supported and funded by the Council to deliver excellent science. These projects to be recognized demonstrate that given the right resources, publicly funded initiatives could be carried on target, and on time. They are truly bright beacons for the science, technology and innovation community.” he said.

The Caraga State University will be receiving two EPIC awards with both projects coming from the public institution. The two projects were also funded by the DOST- Collaborative R&D to Leverage the Economy (CRADLE) Program.

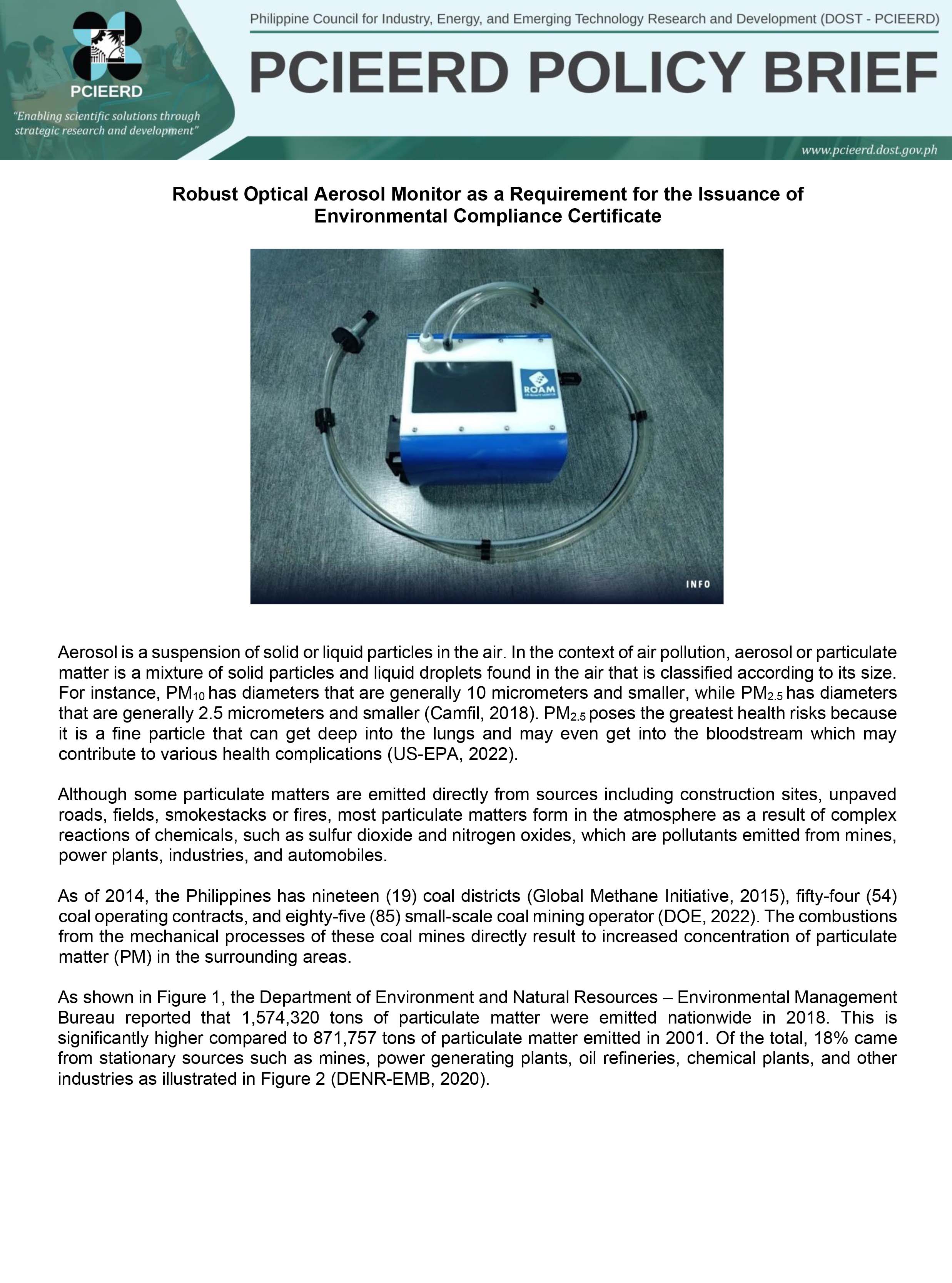

The CYANanobot: Miniaturized Boat-assisted Data Acquisition for Automated Cyanide Monitoring in Wastewater using Optical Nano-sensor, which is a DOST-CRADLE funded project, is used for the continuous and real-time monitoring of the cyanide concentration in the mining tailings pond. It is an automated system using a nanotechnology-enabled module called CYANanobot Sensor for a remotely controlled automated detection and monitoring of cyanide. The project was led by Dr. Alexander T. Demitillo of Caraga State University – Main (CSU) in partnership with Apex Mining Co. Inc.

Also, another awardee from the CSU and a CRADLE project as well, is the Systematized Mining Operations using Automation and Real-Time Telematics Platform towards a Paradigm Shift in Surface Mines of Caraga Region or SMART Mines. The project team developed automation and telematics platforms that monitor and analyze the surface mines' operations. SMART Mines addresses the issues encountered by mining industries in data acquisition and inventory management which dictates how a mine would perform in terms of its profitability and efficiency operations’ flow. The project was also led by Dr. Alexander T. Demetillo in collaboration with Cagdianao Mining Corp.

Meanwhile, Haynayan AR: An Augmented Reality-Based Lesson for the Improvement of Learning Achievement in Cell Biology for the STEM Curriculum was developed to teach complex lessons for Grade 9 and 10 students in the field of science by using AR. The team was able to have a prototype testing of Haynayan AR application and assessed its effectiveness in terms of academic achievement of the students. Haynayan AR was implemented by DOST-Philippine Science High School (PSHS) led by Mr. Joel T. Bautista.

Lastly, a project that transpired from the CRADLE Challenge 2020: Community-level Functionalization of Handwoven Cordillera and Mindoro Textiles for Creative Protective Clothing led by Mrs. Zailla Flores Payag of DOST – Philippine Textile Research Institute has successfully developed a community-based functionalized Philippine handwoven textile solutions for non-medical face masks. This project was in partnership with Custom Made Crafts Center Inc.

Through the CRADLE Program, Filipino companies, including small-to-medium enterprises, find value through innovation by partnering with universities or research and development institutes to solve their problems. The industry partner defines the problem to be solved and the academic institutions or R&D Institute undertakes the research. Funding amounts to P5 million, over a period of one to three years, is given to the academic institution or R&D institute. The industry partner contributes 20% to then project, in cash or in kind; and promises to adopt the research output.

All four projects were funded by the DOST Grants-in-Aid program.